Mercedes-Benz M112/113 Variable Intake Manifold Problems

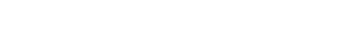

Mercedes-Benz uses a 2 stage dual length variable intake manifold to optimize engine flexibility.

At engine speeds between 1750-3900rpm, the variable intake flaps are closed to utilize the longer runner for improved torque and drivability. At engine speeds above 3900rpm, the variable intake flap opens to utilize the short runner for top-end power.

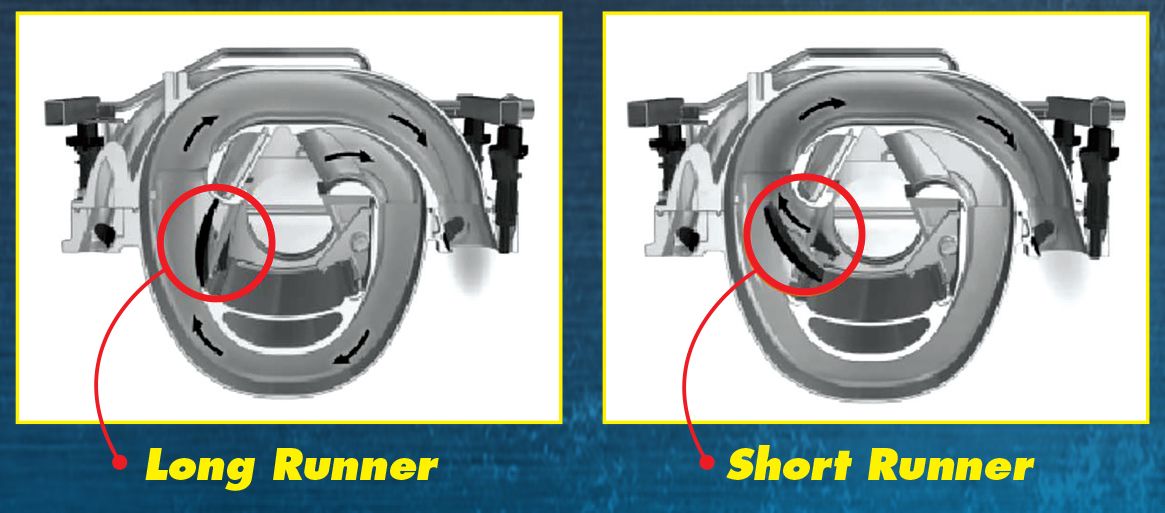

These manifolds use swirl flaps to improve air-fuel mixture at engine speeds below 3000rpm under certain operating conditions.

FAULT/SYMPTOMS

• Increased fuel consumption.

• Loss of low-speed torque.

• Various DTCs relating to variable intake and swirl flap systems Test Procedure.

CAUSES / PROBLEM

• Sticking or seized variable intake flaps.

• Sticking or seized swirl flaps.

• Broken swirl flap switchover linkages, located at the front of the intake manifold (common).

• Vacuum leaks from vacuum diaphragms and vacuum hoses.

• Faulty variable intake and swirl flap switchover solenoids.

TESTS

• Use a vacuum pump to check the operation of all vacuum diaphragms. With vacuum applied, check the variable intake shafts and swirl flaps are moving freely. The variable intake flap will be in the short and

• Check the switchover solenoid operation. (solenoid resistance – Approx. 30 Ω).

• Swirl flap position sensors monitor the flap position (activated/not activated). These sensors (hall sensors) are located at the rear of the intake manifold.

REMEDY

• Replace the inlet manifold assembly if either the variable intake or swirl flaps are seized.

• Replace the inlet manifold assembly if any linkages or vacuum diaphragms are faulty.

For further information and advice, contact a CoolDrive Repair Centre near you.

Find us at...

NSW - Unit 3/25 Garling Road, Kings Park NSW 2148

VIC - 22-28 Lexton Road, Box Hill VIC 3128

QLD - Unit 5/3 Deakin Street, Brendale QLD 4500